Within a couple of weeks, I managed to leave the headlights on while parked at work, and when I came out to drive it a couple of hours later the battery was dead. I knew the battery was likely old and this confirmed it.

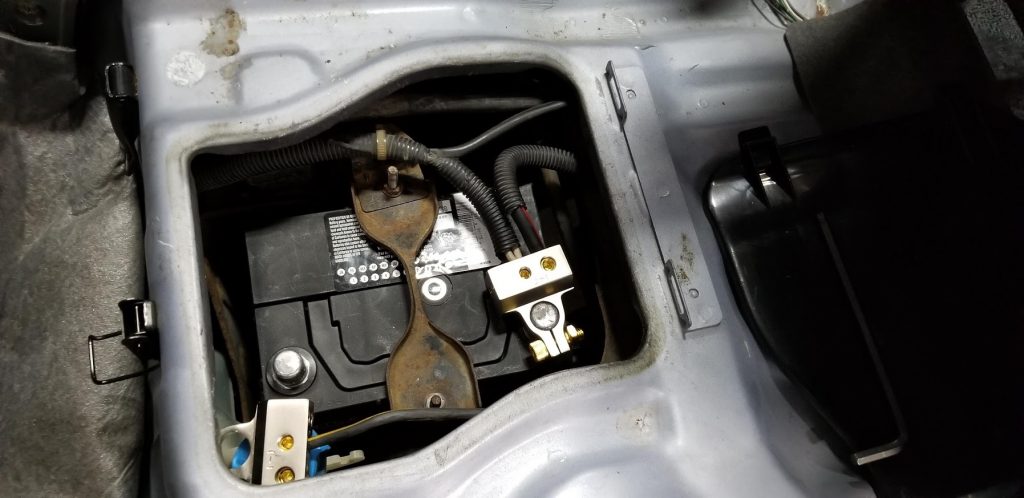

The first challenge was locating the dead battery so we could jump it. It took about 15 minutes, but we eventually found it under the front passenger seat.

The next challenge was finding a replacement battery that would fit. The stock battery labeling was all in Japanese, with the exception of the Mitsubishi logo and the part number 40B19L. After considerable research I ended up choosing Napa part number BAT 65151R, mainly because it was in stock at my local Napa. This battery had comparable specs including overall dimensions and cold cranking amps.

I was in for a bit of a surprise after I got the battery home and tried to swap it, as I discovered that the old battery had pretty small posts, while the new one had a 17 mm negative and 19 mm positive post, which is apparently more of a modern standard. I wasn’t able to force the old clamps to open wide enough to fit around the new posts, so I had to get new clamps on order.

The clamps I chose are this set from Amazon. They are really nice clamps, CNC milled from billet and plated with electroless nickel. From their heft I can tell they are made of either an iron- or copper-based alloy. I was very pleasantly surprised at the quality, especially considering the price tag. They have two main screw terminals on one side and then two smaller ones on the adjacent side that would be great for installing things like stereo amplifiers later. All use metric hex keys.

The only change I had to make was to pry the positive clamp open very slightly because the battery post was a bit too large, but that only took a moment and the installation ended up going smoothly after that. I managed to cut off the old red positive post cover boot from the old clamp and fitted it over the new positive clamp, retained with a zip tie.

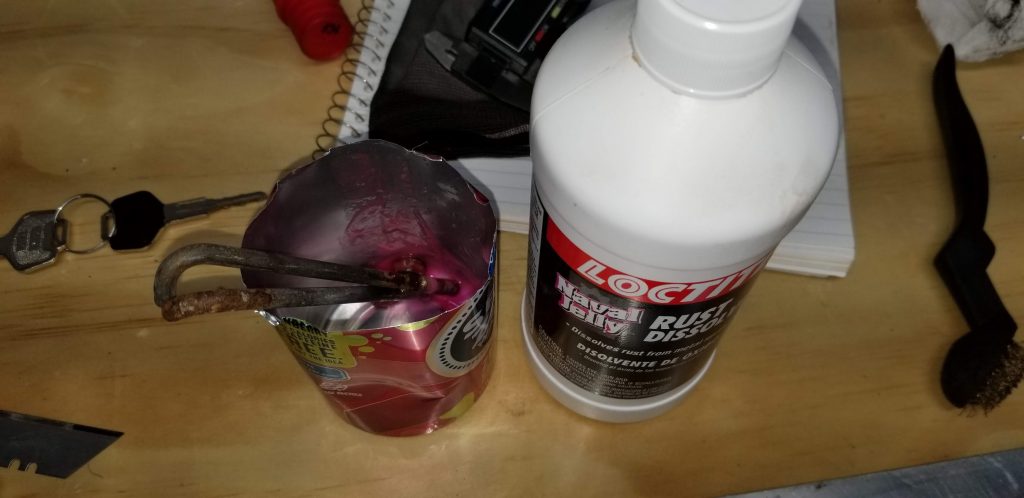

Another point to mention is that the nuts and threaded J-hook rods for the battery hold-down clamp were quite rusty. They came off without needing to break out a torch or penetrating oil, but I wanted to clean them up a bit so they would be easier to work with in the future. To start with, I soaked the nuts and the threaded ends of the rods in Naval Jelly rust converter. This converts the red iron oxide (rust) to black iron phosphate, which can then be scraped off, leaving the bare metal below.

After about an hour, I pulled them out and rinsed off the Naval Jelly, then used a wire brush to strip off the phosphate crud. It was only partly effective, but definitely an improvement. I then put a light coat of copper anti-seize paste on the threads and wiped the excess off with a paper towel. This should help keep the rust down and also prevent the nuts from fusing themselves to the screw threads.